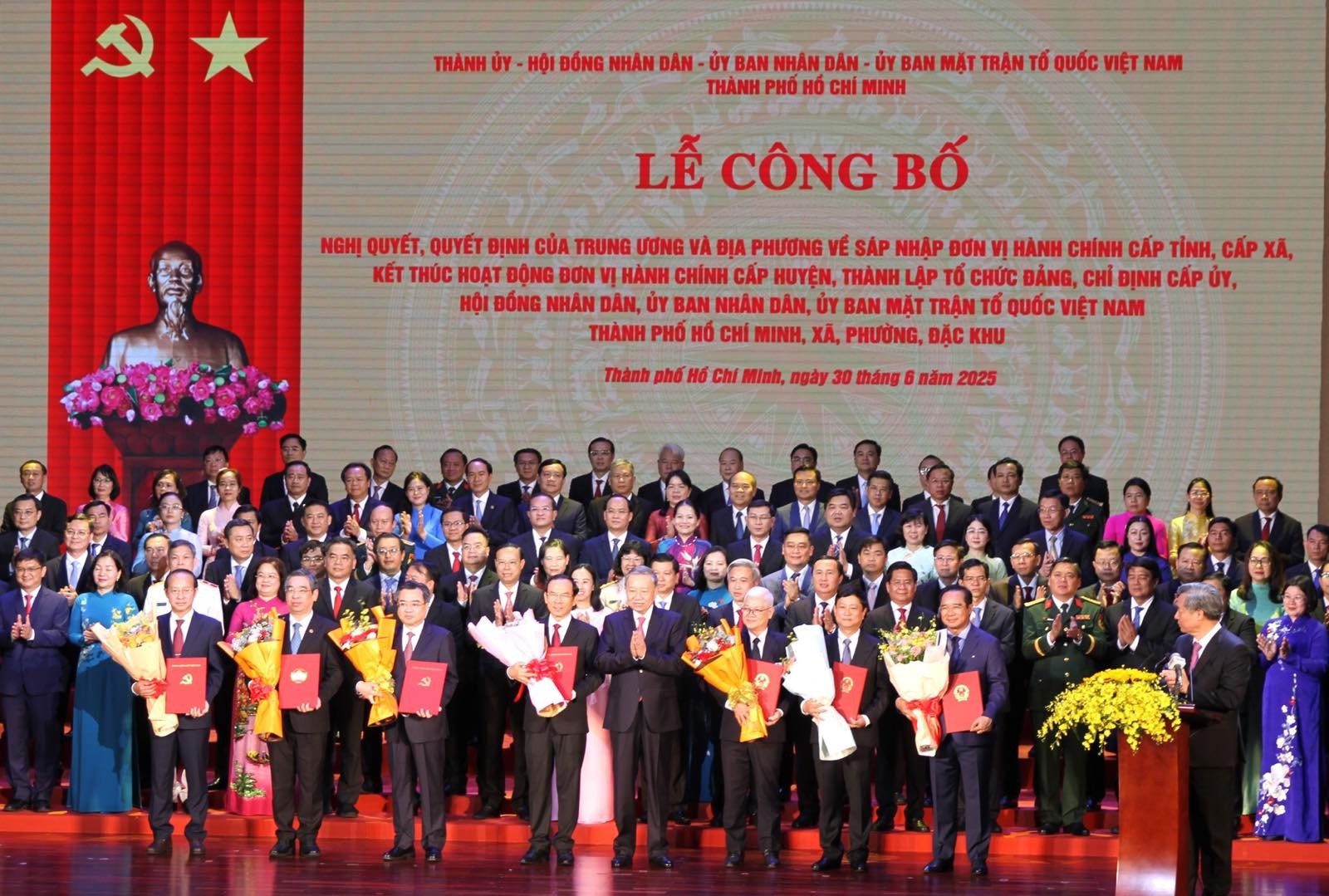

Illustrative photo. (Source: VNA)

A majority of textile-garment companies have orders to fulfill by the end of September, many are in the negotiation process to gain more for the rest of the year.

Nam Dinh Textile Garment JSC (Natexco), a major producer located in the northern province of Nam Dinh, has generated over 1.02 trillion VND in revenue as of the end of May, up 23 percent from the same period last year, according to trade union president Doan Van Dung.

It shows the corporation’s great efforts to address adverse impacts of the COVID-19 pandemic, he said. Natexco had suffered severe labour shortage throughout February and March since there were times when up to half of its workers had to take sick leaves because of COVID-19 infection.

Viet Thang Corporation has been struggling to keep production going during the first quarter of the year, given that the Russia-Ukraine crisis has caused supply chain disruptions and a spike in input and fuel prices and logistics costs, according to Deputy Director-General Dau Phi Quyet.

Those expenditures have climbed three- to four-fold, so all units were having hard time figuring out possible ways to get out of the situation, Quyet said.

Though the company has managed to find stable supplies of inputs, it is having a shortage of imported replacements for equipment components to deal with. It took six to eight weeks to receive deliveries of the replacements, which normally came from the Europe. Now the shipments may take up to 12 weeks to arrive.

To cut costs from logistics services, the corporation is prioritising major orders instead of the small ones.

Vietnam National Textile and Garment Group (Vinatex), one of the leading textile-garment manufacturers in the country, had impressive business performance since the start of this year with a 50-percent surge in revenue. But similar challenges could potentially put the brake on its growth over the remaining months.

Record inflation in decades are ravaging major economies, including the US, the EU and the UK, triggering rising inventories and declining purchasing power. This may have substantial effects on Vinatex’s performance, CEO Cao Huu Hieu said.

To weather the crisis, Hieu has advised domestic manufacturers to prepare themselves with more flexible plans in order to promptly address any market changes.

He attributed the company’s Q1 positive business results to its ability to secure stable and sufficient supplies of inputs. Vinatex has invested on several yarn production projects using modern technology between 2015 and 2020, two of which were put into operation last year./.

Q.Hoa t.h / VNA